|

1. For Thermal or Atomic Power Plant

2. For Hydraulic Power Plant

3. For Compressor or Pump Parts

4. Duplex or Super Duplex Stainless Steel

5. For Iron, Steel & Nonferrous Metal Making

6. For Crusher Plant, Civil Engneering

7. For General Industries & Ships

|

|

|

1. For Thermal or Atomic Power Plant

|

|

|

Turbine Casing

Cr-Mo-V

13,000kg

|

|

|

|

Outer Casing (Upper)

Cr-Mo-V

16,700kg

|

|

|

|

HP Inner Casing

Cr-Mo-V

10,000kg

|

|

|

|

Main Stop & Control Valve Casing

G-X12CrMoWVNbN10-1-1

9,200kg

|

|

|

|

Main Stop Valve Casing

G-X12CrMoWVNbN10-1-1

8,500kg

|

|

|

|

Control Valve Casing

Cr-Mo-V

11,500kg

|

|

|

|

Combined Reheat Valve Casing

Cr-Mo-V

11,100kg

|

|

|

|

|

|

2. For Hydraulic Power Plant

|

|

|

Francis Runner (2pieces Type)

JIS SCS6

Band+Vane:5,000kg , Crown:5,000kg

φ2,900mm

|

|

|

|

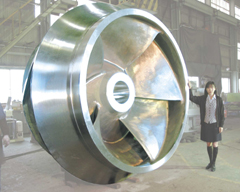

Francis Runner

(2pieces Type after FABRICATED)

JIS SCS6

15,500kg φ3,330mm

|

|

|

|

Runner Band

JIS SCS6

5,600kg φ3,300mm

|

|

|

|

Kaplan Runner, Runner Vane

JIS SCS6

4,000kg

|

|

|

|

Pelton Runner, Bucket Wheel

JIS SCS6

7,000kg φ2,750mm

|

|

|

|

Francis Pump Runner

(2pieces Type after FABRICATED)

JIS SCS6

15,100kg φ3,150mm

|

|

|

|

|

|

3. For Compressor or Pump Parts

|

|

|

Suction Casing (Lower)

ASTM A27 Gr.70-36

6,860kg

|

|

|

|

Cylinder Body

JIS SCS13

3.200kg

|

|

|

|

Spiral Casing

JIS SCS14A

12,700kg

|

|

|

|

Impeller Liner

JIS SCS13

1,530kg φ2,860mm

|

|

|

|

Discharge Elbow

(Sea Water Pump for Nuclear Plant)

GSCS16

2,500kg

Discharge Tubes

GSCS16

500kg

Licensed by Advanced Nuclear

Equipment Research Institute

|

|

|

|

HP Codensate Pump Casing (Upper/lower)

for Nuclear Plant

JIS SC450

Upper : 5500kg , Lower : 10,100kg

|

|

|

|

Compressor Body for Super Low Temp.

ASTM A352 Gr.LC9(9%Ni)

Upper : 6,200kg , Lower : 7,300kg

|

|

|

|

|

|

4. Duplex or Super Duplex Stainless Steel

|

|

|

Impeller

ASTM A890 Gr.6A

( CD3MWCuN, PREN.≧40 )

8,300kg φ2,900mm

|

|

|

|

Double Suction Volute Casing

ASTM A890 Gr.5A

( CE3MN, PREN.≧40 )

6,700kg

|

|

|

|

Impeller

ASTM A890 Gr.6A

( CD3MWCuN, PREN.≧40 )

2,000kg φ1,700mm

|

|

|

|

Double Suction Volute Casing

ASTM A890 Gr.1A ( CD4MCu )

9,000kg

|

|

|

|

Discharge Bowl

ASTM A890 Gr.5A

( CE3MN,PREN≧40)

5,000kg

|

|

|

|

|

|

5. For Iron, Steel & Nonferrous Metal Making |

|

|

Mandrel Segment

YST5

1,100×4 = 4,400kg

|

|

|

|

Drum Segment

YH24-12S4tN

12,500kg

|

|

|

|

Bell

YahC1S1(H-C・Cr)

12,000kg φ4,000mm

|

|

|

|

Sink Roll Hunger

YH24-12S4, YHZ1

1,000kg

Snout

YH24-12S4, YHZ1

1,600kg

|

|

|

|

|

|

6. For Crusher Plant, Civil Engneering

|

|

|

Mantle

H-Mn Steel (20Mn,HC)

|

|

|

|

Concave Ring

H-Mn Steel (12〜30Mn,HC)

|

|

|

|

Jaw Plate

H-Mn Steel (12〜30Mn,HC)

|

|

|

|

|

|

7. For General Industries & Ships |

|

|

Resin Machinery Parts

JIS-SCW480

8300kg

|

|

|

|

Connecting Rod

JIS-SCMn3A

3,500kg

|

|

|

|

Main Bearing Support

SC410

7,200kg

|

|

|

|

Connecting Rod

SC480

1,600kg

|

|

|

|

|

|

|

|

|

|

|

|

YONAGO YS RECUPERATOR is a high efficient heat-exchanger

which utilizes waste gas heat to save energy consumption.

We are proud to say that this recuperator is designed on our vast experience

and expertise, proved by our supply records of over 40 years.

Thus its superior performance is highly recognized by its many users.

|

|

|

|

|

------For preheating combustion air, fuel gas and others.------

|

|

|

|

|

STEEL PIPE TYPE RECU.(Suspended type)

|

|

■ For Iron and steel Plant

Re-heating furnace. Heat-treatment furnace.

Soaking pit. Electric furnace.

■ For Non-ferrous metals Plant

Melting furnace. Re-heating furnace.

Heat-treatment furnace. Electric furnace.

■ For Steel casting and forging Plant

Heat-treatment furnace.

Re-heating furnace. Electric furnace.

■ For Ceramics Plant

Tunnel kiln. Melting furnace.

■ For Others Industrial Plant

Incinerator. Air Heater.Etc.

|

|

|

|

|

|

|

|

|

■ Efficient Performance

|

The RECUPERATOR is designed after years of research and the compilation of large quantities of test-data,

which guarantee its excellent performance and endurance in severe conditions. Increasingly high efficiency is

required(for example Temp-efficiency=0.9)and the actual data of YONAGO YS RECUPERATOR satisfies

these specifications and YONAGO's strict calculations. The RECUPERATOR is highly regarded by its users.

|

|

|

■ Durability

|

Each and every part of the equipment is built for excellent durability, especially the heat transfer element,

which uses a high chrome ferrite steel pipe or casting fin-tube, known for their good heat and corrosion

resistance against high temperature waste gas.

|

|

|

■ Simple Structure Easy Maintenance

|

Simple structures and flexible joints are specially constructed for thermal expansion and thermal shock,

meaning the RECUPERATOR requires less maintenance.

|

|

|

■ Reliability

|

Manufacturing of YS RECUPERATOR is carried out on YONAGO's premises, under strict quality control

conditions that ensure reliable, high quality equipment is supplied to our users.

|

|

|

|

|

STEEL CASTINGS(FIN-TUBE)TYPE RECU.

|

|

PATENT No.619632

|

|

|

|

|

|

|

|

We design

the most suitable type of

YONAGO YS RECUPERATOR

in accordance

with your requirements.

|

|

|

|

|

|

|

Channel Type

W1,300×L2,800×H4,300mm ×8Ag

8,300kg/Ag

For Reheating Furnace

|

|

|

|

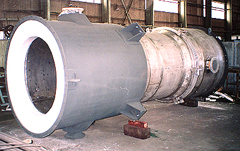

Radiation (+Tube)Type

φ1,900×H4750mm

9,800kg

For Incinerator

|

|

|

|

Shell & Tube Type

φ2,400×H3,900mm

13,500kg

For Cold Mill/CAL Furnace

|

|

|

|

Radiation (Double Cylindrical) Type

φ1,400×H5,200mm

5,000kg

For Incinerator

|

|

|

|

|

|

|

|

|